In 1992, with lots of enthusiasm and little experience, Klaus Wohlfarth opened a small retail outlet in his home town of Murrhardt in Swabia. In a small company called “KW Tuning” he initially worked alone, and then later with his brother, successfully selling car accessories and hi-fi car products in the region. Situated in a dilapidated building, the first shop was no more than 75 square meters in size and had expanded little by little to include a garage.

The year 1995 marks the first important milestone in the company’s history, and was the basis for today’s success. Out of frustration at the quality of the products on the market and even more disappointed with the available functions the current solutions offered and didn’t deliver, they decided to create their own solution by manufacturing a height-adjustable suspension with the help of a friend. Throwing caution to the wind, they went ahead against all odds.

This is when the KW Tuning coilover suspension – the first suspension on the market with defined and tested height-adjusting – came into being. It all began with some KONI standard dampers which had to be extensively modified. As the requested support of other established damper manufacturers declined, they continued to draw on the KONI catalog, in the process buying out almost every article on the market for certain products. With the subsequent manufacturing of special cartridge dampers, KW became one of the Dutch manufacturer’s biggest customers.

A change of strategy heralded the end of the collaboration – and the beginning of their own damper development and production on the KW premises. Since 1999 they have developed numerous valve systems of their own, and now produce as many dampers in one day as they did in one year at that time.

The First Challenges

After the young businessmen had done all of the necessary material strength tests, endurance tests, and assembly trials, the TÜV gave its blessing in the form of a technical component report. This meant that the innovation could be presented to the public for the first time at the 1995 Essen Motor Show. The overwhelmingly positive reaction led to them starting the production of coilover suspensions for trade in a 150 square meter warehouse in the village of Klingen at the start of 1996.

From then on, in this “chicken yard”, a technically-versed triumvirate also worked on the further development of products. Alongside the Variant 1 coilover suspensions with a fixed damper setup, one development in particular came to the front – the height adjustable rear-axle springs. The unsuspecting entrepreneurs introduced these innovative height adjustment mechanisms and rear-axle springs to the market without any patent protection, and as a result of their success, there were soon numerous unauthorized copies.

Yellow/Purple became the Brand…

Today the colors “yellow” and “purple” represent the attributes of our products in the same way as the letters KW themselves – and are just as strong of a mark. And who would know that the first KW coilover suspensions featured no yellow or purple parts at all? It is purely by chance that the anodized parts were delivered with a purple color instead of the shade of blue that had been ordered, and because the red springs didn’t match these aluminum parts, they were quickly painted yellow and marked with stick-on letters. Out of this necessity, we made a virtue, in the process creating one of the strongest brands in our industry. The internationally-registered color trademark has a high recognition value and clear differentiation from other product suppliers.

With the move to Fichtenberg and the transformation of the joint partnership into “KW automotive GmbH” in 1998, the Wohlfarth brothers had paved the way for the growth of their young business. In the same year as the purchase of the 1,050 square meter manufacturing plant, the administration building was established and a further factory commissioned – even though at the beginning of the year it seemed that the then five employees had more than enough space at their disposal.

In the following years, further warehouses and manufacturing plants were constructed and major renovations were undertaken to repurpose existing buildings, resulting in a factory space over 23,000 square meters.

This period of intensive construction was brought to an end in 2006 with the launch of the new 7-post test stand, for the time being. From the early days the Wohlfarth brothers, were experienced race car drivers, and have been committed to motor sports.

In 1999, they founded the KW racing team and were able to persuade the only woman ever to have won a DTM race to join them: Ellen Lohr. From then on her name was connected with KW, and over the years was an ambassador for the KW brand. Launching their own racing team in the DTC series didn’t just mark the inception of KW competition racing suspensions, but more impressively it demonstrated the technical competence of the whole team with the construction and operation of the race cars.

From the chassis to the suspension, right up to the engine, the entire electronics system and the transmission were all developed autonomously, and manufactured in their own factories as well as tuned on their own test stands. A race car which had been unknown up until that point and was inferior on paper – a 1.8 liter Honda Integra – caused a sensation and was successfully employed by its own team for a year.

At the same time, they were able to employ an STW Honda Accord with a second team in the Super Touring Car Championship of the same name, which they supported as a regular sponsor.

In order to cope with the growth in the sector, after this debut season, they concentrated on out kitting the competitors and the gaining new customers, so that little by little they could expand their commitment to motor sports as the supplier for numerous national and international race teams and series.

A historic motor sports success in 2002 marked the beginning of a new era in KW’s commitment to motor racing. We celebrated our first overall victory in the toughest long-distance race in the world: the ADAC Zürich 24h race at the Nürburgring. Since that victory by the legendary Zakspeed Viper on the Nordschleife, KW has been considered a reliable partner and has become the biggest supplier of suspensions at the long-distance race in the Eifel region.

Alongside countless class victories in the VLN and the 24h race, the suspension manufacturer celebrated five additional overall victories with the Manthey Porsche in the “Green Hell” – the most demanding race track in the world.

The Next Suspension Revolution

With the experience gathered from motor sports, the coilover suspension pioneers worked on another innovation that they presented at the 2001 Essen Motor Show: the KW Variant 3! The coilover suspension with ist patented technology for the separate and independent adjustment of compression and rebound stage damping enables a considerable sportier tuning of vehicles as well as good ride comfort – a true revolution. The introduction of the Variant 3 also laid the foundation for an even more brilliant idea by the Wohlfarth brothers, which once again revolutionized the market – in terms of housings, KW focused on stainless steel and launched the Inox Line product range.

After the thoroughly positive experience of manufacturing rust-free stainless steel suspension struts, in 2002, the entire range of KW branded suspensions was changed over, and today all suspension struts are, without exception, made from stainless steel or aluminum. This impressive commitment to quality supports KW’s philosophy today.

RaceRoom – Motor Sports for Everyone

As a former motor sports driver, Klaus Wohlfarth knows the emotions experienced by every race car driver who has been set free behind the wheel of a competitive race car.

Being able to experience these very emotions in a simulator led to the pursuit of a new vision on the KW premises: since 2009 anyone who wants can launch a racing career and test themselves against other race drivers in the RaceRoom.

Growth – Strategy

The year 2001 is another milestone in the growth of the company and also a new experience. KW automotive GmbH takes over a competitor and with it the WEITEC brand, which from this point is established as an inexpensive alternative to KW’s premium suspensions, and resulted in the expansion of their product portfolio. At the same time it was also a landmark decision that resulted in a very successful multi-brand strategy by KW automotive GmbH in which the various products and market segments are recognizably differentiated still today. In Switzerland, with Weitec Fahrwerktechnik AG – later KW (automotive) Schweiz AG – the Wohlfarth brothers found their first foreign branch and start the internationalization of the company.

In 2005, with the takeover of the assets of the U.S. suspension manufacturer “Belltech Sport Trucks and Suspension Techniques” the expansion of the German company from the Swabian village of Fichtenberg to America begins. The truck and SUV components of the Belltech brand, in particular, were an ideal addition to the KW product range that had been a success in Europe, and under the new umbrella of KW automotive NA Inc., and the expanded product portfolio could successfully be placed in the established commercial structures.

From that point on, both American and German engineers worked together to develop further products at the new headquarters in Sanger, California, where the majority of the product range for the American market is manufactured. Then, in 2015, the company headquarters was relocated to Clovis, a suburb of Fresno/California, where 60 employees now conduct daily business for the North American market in a modern and prestigious location. n order to provide the best possible service to the core markets for all of the products of the enterprise group’s various brands, KW has systematically set up its own branches with specially trained employees. Since 2006, customers in the British Isles have been served from a base in England. KW has been represented on the rapidly growing Asian markets since 2008 with its own subsidiary in China and with the founding of an agency in Taiwan in 2016 this boom region has been further consolidated.

Trendsetter – Lambo Style Doors.

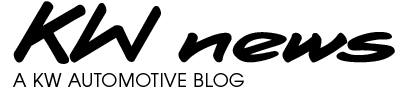

Always open to new ideas and with the foresight of a successful entrepreneur, Klaus Wohlfarth had his sights set on more than just suspensions. While visiting the SEMA tuning and accessories trade fair in 2003 he came up with the idea for a new product: LSD – Lambo Style Doors. However the universal kits he saw at the trade fair didn’t come close to meeting the safety requirements of the German testing organizations and fell very short of the quality standards of KW’s engineers. From that point they took charge on the development of the product range.

Amid major visitor interest and an unexpected media response, the retrofittable “Lambo doors” are presented for the first time six months later at the 2004 Tuning World Bodensee, and additional vehicle-specific solutions subsequently presented to the North American public at SEMA 2004 with superstars like Snoop Dogg, Nelly, Chingy and boxer Bernard Hopkins. These products quickly attracted interest, even among vehicle manufacturers. In order to satisfy the demands of this clientele, the operational safety of these solutions was demonstrated in crash tests. Today “Lambo doors” are available for a variety of small, mid-range, and super cars like the Audi R8, Lamborghini Gallardo etc.

OEM Projects – New challenges that benefit all of our customers

The setting up of our 7-post drive dynamics test stand has increased the awareness of our capabilities at our Fichtenberg location as well as the interest of vehicle manufacturers in our products and technologies. The test stand facilities, normally used by Formula 1 racing teams, make it possible to simulate almost any driving situation under laboratory conditions.

This gives motor sports teams and industrial partners the chance to tune vehicles in an objective and efficient way by simulating a wide variety of road conditions or testing programs directly on the test stand. This allows us to systematically develop new suspension solutions which optimize performance and ride comfort together with our customers.

In collaboration with engineers from AMG, the first OE coilover suspension was developed for the Mercedes Benz SLK 55 AMG Black Series, with KW contributing to further Mercedes AMG Black Series models. Other suspensions are being developed in collaboration and manufactured on location in Fichtenberg. Vehicles such as the CLK 63 AMG Black Series or the SL 65 AMG Black Series display the highest levels of performance in their vehicle classes and have already achieved cult status today.

With the success of these vehicles, there is a growing interest by other manufacturers to collaborate and in subsequent years we have worked (in some cases continue to work) together with almost all vehicle manufacturers in the development of special suspension solutions for prototype vehicles and low volume production performance vehicle models.

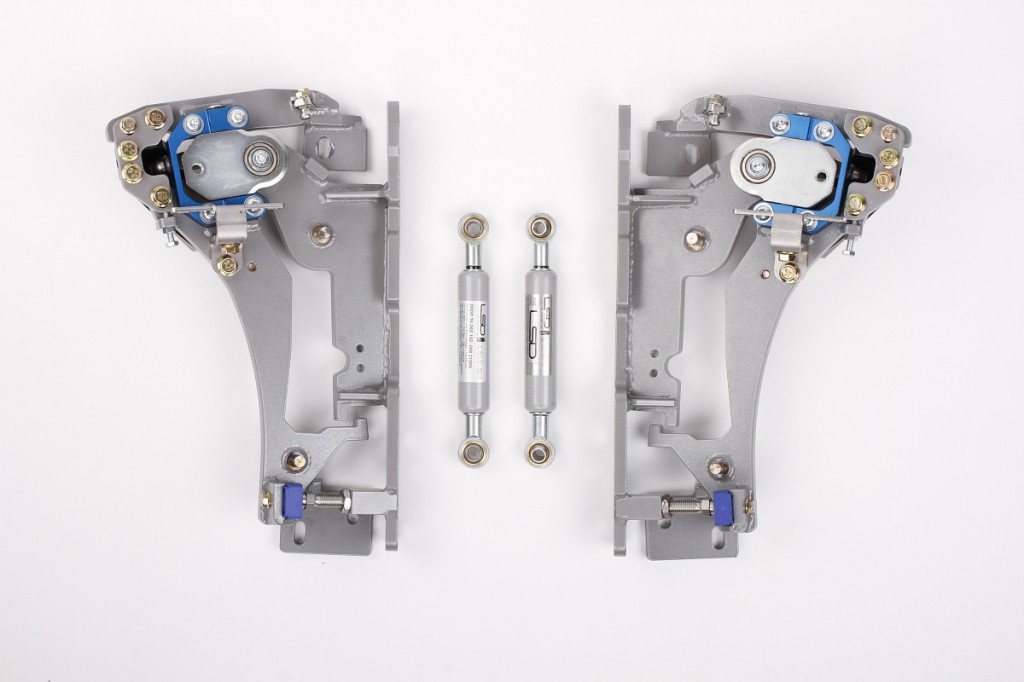

In the course of our collaboration with our OE customers, we not only developed new processes for production, quality assurance, and monitoring of the products themselves, but often developed completely new technical solutions which have found their way into the aftermarket range like the KW Hydraulic Lift System, for example. Originally used in DTM/ITC race cars, this system allows vehicles to be hydraulically raised or lowered by up to 45 mm at the touch of a button.

The HLS system is particularly popular in the super car segment and with the quick raising of the vehicle the necessary ground clearance can be attained. However, in the Show & Shine segment too, this technically demanding system is used to achieve the lowest possible suspension setting.

The Evolution of KW Coilover Suspensions

Customer feedback from international markets leads to more innovative, technically-detailed solutions: this is the reason the adjustable coilover spring seats, which were originally made from aluminum, are now manufactured using polyamide composite materials with incorporated stainless steel reinforcement. This has also resulted in the further improvement to their corrosion resistance and has made the spring seat considerably easier to adjust.

Since 2010 the independently adjustable dampers in the compression and rebound stage have been fitted with respective click settings and scaled adjusting dials – something which has considerably simplified the application and tuning of the vehicles.

Conquest of the Nordschleife

With the Dodge/Chrysler OE customer project, a new generation of coilover suspensions is being established: the ACR-X Viper SRT10 is factory-fitted with a 2-way adjustable suspension in a lightweight aluminum design which helps the vehicle to achieve maximum performance, leading to an impressive new Nordschleife lap record for production vehicles at 7:22:1 minutes. The 2-way and 3-way adjustable Clubsport suspensions which are based on that are a result of the further development of the original Viper project.

Why we developed Variant 4

In 2015, the 3-way adjustable Clubsport suspension was used as the basis for a new OE project and the BMW M4 GTS. Introduced to the market in 2016, it is factory-fitted with a completely revised damper system which is now adjustable for rebound and 2-way compression stage damping. The first BMW fitted with a 3-way adjustable coilover suspension as standard, currently represents the peak of the performance vehicle range.

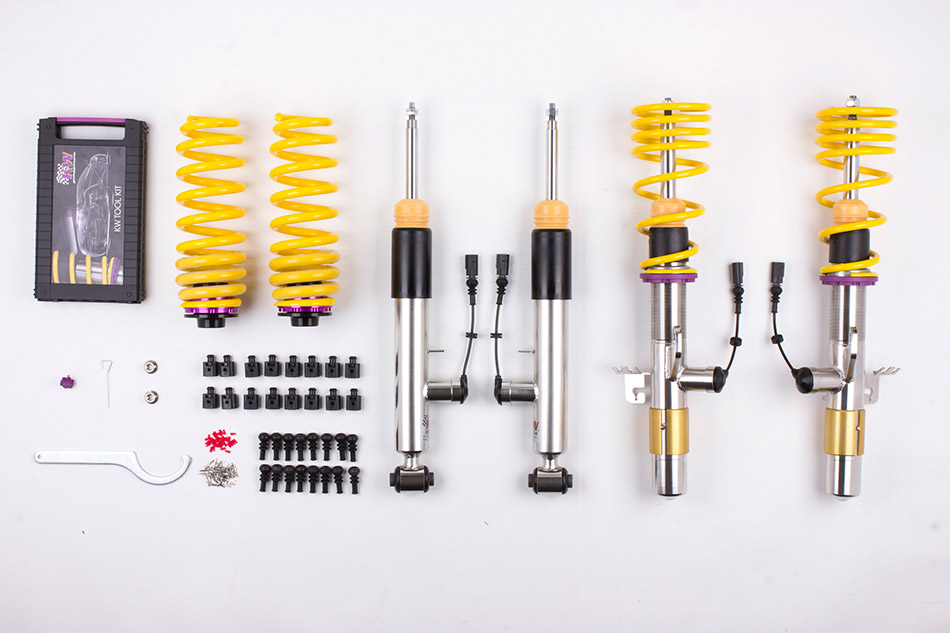

However, it’s not just the rare owners of the BMW M4 GTS who stand to gain from this innovation. With the introduction of the Variant 4 in the 2017 season, the owners of other sports cars can draw on this technology and optimize the performance of their vehicles with an 18-way adjustable rebound stage damping, 14 click settings in the highspeed compression stage and 6 click settings in the low-speed compression stage.

Adaptive KW DDC Technology – the Aftermarket Revolution

With the DDC plug and play coilover suspension, KW automotive is meeting a new challenge on the suspension market with another intelligent innovation. Select vehicles with standard, adaptive dampers can now be controlled via the standard electronic system and adjusted to the designated steps.

Here the KW suspension struts simply replace the standard damper/spring combinations and the electronic connection is made with the original connectors. This allows the on-board electronics to recognize the adaptive damping system and regulate the control valve within milliseconds. For vehicles without standard electronic dampers, or for customers who want even more adjustment options, the innovative KW DDC ECU damping system has been available since 2011. In addition to the suspension struts with DDC (Dynamic Damping Control) valve, a cable harness, Wi-Fi module and a control unit with software are also included in the package.

The damper settings can be individually configured via the KW DDC app. As well as three fixed settings (comfort, sport, sport+), the driver can also establish direct contact with the dampers and adjust the characteristics at the touch of a button and record his/her own characteristics. As the valves react in a matter of milliseconds, the driver will immediately feel the changes, empowering them to become an active “setup engineer” in the process.

In 2012 the family of “app-controlled KW suspensions” was complemented by another innovative product, the electronic DLC suspension lowering module. It allows the user to set the height of vehicles with standard air suspension at the touch of a button through individually defined steps or millimeter by millimeter.

In order to cater to market conditions and the changing needs of customers throughout the years we have developed new technologies and with those, new applications. Although, more importantly, we have also improved our manufacturing processes.

While in the early years the coilover suspensions were assembled in large quantities, packed and then sent to our shelves and our customers‘ warehouses, today every suspension is individually made-to-order for a customer. This not only guarantees that customers with very different wants and needs get the right KW suspension, but also means we can guarantee that every KW suspension measures up to the cutting edge of technology and customers aren‘t receiving just any old stock.

The manufacturing of “production batch 1” imposes very particular requirements on the vertical range of manufacture, which is why almost all parts are manufactured on-premises in takt time. The logistics and assembly processes have also been optimized and refined throughout the years.

Thanks to their exceptional flexibility, our qualified employees can manufacture any of our myriad products at short notice and able meet the demands of our customers. This also includes the desire for exceptionally high quality which we can guarantee thanks to the numerous quality assurance measures that have been integrated into the manufacturing process.

The Original Equipment Manufacturer Business is still growing

These unique structures, our technologies, and the corporate philosophy of being able to manufacture individual suspension solutions according to customer and market needs, result in a more intensive collaboration with almost all vehicle manufacturers. As a result, the John Cooper Works Pro sports suspension developed by KW and produced in Fichtenberg is officially marketed for the three-door MINI Cooper (F56) via BMW Mini AG‘s dealership network.

KW also kits out the Mercedes-Benz G 500 4×4² with dampers. At the 2017 Wörthersee meeting, Audi will be presenting a real jaw-dropper in the form of the TT Clubsport Turbo Concept. The 600 hp sports car has a KW coilover suspension system including HLS lift system. One hundred percent precision, first-class quality, technical expertise, innovations from the race track adapted for the road: you‘ll find all of this packed into the suspension solutions from Fichtenberg.

Preparation for future growth

In 2016 the most extensive construction and investment projects in the history of the young company were set in motion. A ready-made assembly hall and development workshop (2,700 m²) will be complemented by a modern office (1,200 m²) for the 40+ technicians and engineers who are now employed there. A new warehouse and logistics center (2,000 m²) is also being built. For 2018, exactly 20 years after the purchase of our first building in Fichtenberg, we are planning to complete the 3,000 m² office building. With this commitment to our headquarters and our 220 current employees (over 300 employees worldwide) we plan to continue driving innovation in the suspension sector. Here’s to the next 25 years…

Words / Images MediaTel, KW archive