Within the framework of the “Strategy for Artificial Intelligence”, the Federal Government of Germany supports the transfer of fundamental research into the economy. KW automotive, the suspension manufacturer, with its expertise in the development and production of adaptive coilover suspensions as well as chassis control units, is firmly involved in this process. This research, which is supported by the German Federal Ministry of Education and Research as a partner in the joint project “Development of AI-based suspension control systems” (HT: KIFAHR) together with the “Deutsches Zentrum für Luft- und Raumfahrt e. V. (DLR, German Aerospace Center).

“The project aims to achieve greater automation of the controller design process and at the same time better adaptive control properties for semi-active spring/damper units in the chassis segment for vehicles. To achieve this, intelligent learning methods, so-called supervised learning and reinforcement machine learning, are to be used on the foundation of real measured data both for model development and for the programming of the controller,” explains KW development engineer Michael Rohn.

By using efficient and robust AI algorithms, it is possible to gather complex non-linear interactions in the overall chassis. By using machine intelligence, it will be possible in the long term to develop and adjust vehicle suspension. “So basically, KW automotive is working on intelligent KW coilover suspension for tomorrow, in which the damping is adjusted autonomously”.

KW automotive competence cluster for adaptive chassis control systems

Over the past years, KW automotive has built up significant expertise in the development and production of adaptive coilovers, KW software control systems, KW suspension control units and KW electromagnetic damper valves. The chassis manufacturer works in close cooperation with DLR. DLR has developed a software control solution for adaptive suspension dampers together with KW automotive.

These KW components are already used in selected vehicles from car manufacturers, such as the Mercedes-Maybach G650 Landaulet and Rimac C2. The new KW dampers with solid piston design technology, as used by the suspension manufacturer in the new KW Variant 5, are also suitable for adaptive systems.

In our adaptive DDC suspension for the Mercedes-AMG G63, we use two electronically controllable proportional electromagnetic valves.” continues Michael Rohn. “With a chassis control system supported by AI, we supply an answer to the ever-increasing demands of our customers.”

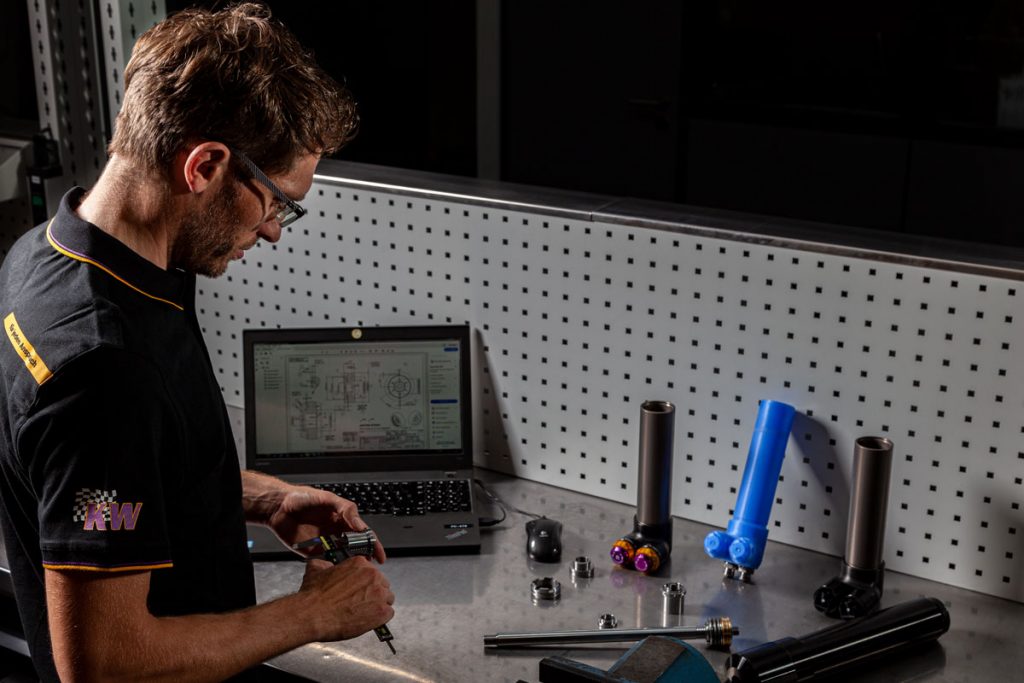

Michael Rohn has been working in the R&D department at KW in Fichtenberg for more than eleven years and started working on the control of adaptive coilover suspensions at KW automotive when he was still a diploma student.

Today, Michael Rohn works as department director in the suspension development at KW. Many of the engineers working at KW automotive started directly as diploma students at the suspension manufacturer.

Start your Carreer at KW automotive

KW automotive has been for many years a global market leader in its segment and continues to grow. Currently, almost 30 young people are in an apprenticeship at the suspension manufacturer. For years, KW automotive has received several awards from the Chamber of Industry and Commerce for its exemplary commitment to training and education. KW also offers university apprenticeships in business administration, vehicle systems engineering, or industrial engineering.

Images KW, Shutterstock