You only get confused when it comes to suspensions? No problem! We’ll help you out. Modern coilovers offer much more than just the option of a continuous lowering or damper adjustment. Today, there are coilovers available with adaptive damper control that is compatible with many suspension systems of the automotive industry.

Some can be adjusted in damper characteristics by smart phone. With others, the dampers can be adjusted individually as in motorsport in the low speed and high speed compression damping as well as rebound damping and many other parameters. In this “Suspension Wikipedia” we will introduce important features to you.

The job of a suspension kit

Part of the suspension kits are damping elements consisting of damper, spring, top mounts and bump stops. For the wheel guidance itself, the suspension such as transverse links, wheel bearing, wheel carrier, etc. are responsible. Of course, wheels, tyres and stabilizers are also part of the suspension components. For the driving behavior, essentially the dampers, springs, stabilizer and elastokinematics of the transverse links are responsible.

Suspension springs

The main task of the springs is to carry the weight of the vehicle and they are responsible to ensure that the car is at a certain level of height. Springs store the “impact energy” acting on the car during compression and convert it into vibrations. In conjunction with the dampers and the wheel suspension, they keep the car controllable.

Spring rate

It describes the stiffness (hardness) of the spring. The higher the spring rate, the more force is needed to compress the spring. The unit for this is N/mm or as a rule of thumb kg/cm, which means to compress a 70N/mm spring for 1 cm it requires 70kg of weight. The spring rate in particular takes influences on the frequency of the vehicle chassis.

Stiffer springs lead to a high construction frequency and have the advantage that the vehicle lowers a little when loaded. In curves, the body tilts less. At too hard spring rates, the vehicle significantly loses ride comfort and ultimately also grip. Here it is important to find an optimal compromise. Depending on the design, it differs between linear and progressive spring rate. Linear spring rate is when the spring rate remains the same over the full travel, but with a progressive spring, the spring rate increases over the range of spring.

Dampers

Dampers, technically correct vibration dampers, control the relaxation of the spring (rebound). Simply described, the compression is needed to support the spring. The primary task of the dampers is to reduce vibrations of the body. In addition, the dampers can also affect the vibrations of the wheels. The energy released by the spring is transmitted via the piston rod to the dampers.

In the resulting piston rod movement, kinetic energy is converted into heat; the physicist speaks of dissipation in the thermo dynamics. Depending on the forces acting on the piston rod, up to 90°C and more can occur. For all suspension systems, the dampers are the essential instrument to influent the driving dynamics.

Especially sport suspensions and coilovers the dampers are the most important components to get a sporty driving behavior. Depending on the version of the damper, also the hydraulic resistances can be changed by adjustable valves in order to take influence on the damping level in detail.

There are different damping technologies

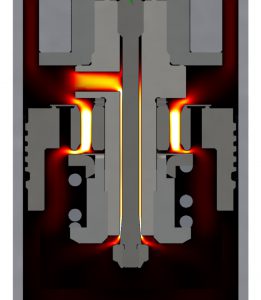

Vibration dampers aka suspension dampers are commonly used in OEM and aftermarket applications as “twin-tube dampers” or, more rarely, as “mono-tube dampers”. In both damper types, a piston moves in an oil-filled cylinder. The piston conveys the oil through valves. In the valves, the resistance of the oil flow is influenced. There are so many different valve systems available, it would just take too long to explain all of them.

If a car deflects while driving, the pressurized oil is displaced by the immersing piston rod. Inside the damper, there may be several valves for the rebound and compression stages. These are necessary to present different force increases at low and high piston rod speeds. These systems are usually found in high-end performance applications, such as KW or ST coilovers.

Single-tube (mono-tube) dampers (left) consist of a housing in which a piston rod moves during rebound and compression by a cylinder filled with hydraulic oil and under pressure (gas). The fluid must flow through valves in the piston from one side to the other. This creates a resistance where the damper force is generated. Compared to the twin-tube damper, mono-tube dampers require a higher gas pressure. Usually, the gas and oil volume is separated by the separating piston. The twin-tube damper (right) consists of a damper housing and the cylinder tube which is located inside the damper and leads the working piston. During compression, the damper oil under pressure flows from the cylinder tube through the bottom valve into the outer housing. When rebounding, the oil flows through the rebound piston, which is working directly in the inner tube. The previously displaced oil is passed through a check valve back into the cylinder tube.

Adaptive dampers

In the past, there were coilovers and sport suspensions, which could be changed in damper characteristics by electronic actuators on the piston rod. Today, this works with the help of electromagnetic valves installed in the damper, within milliseconds, as proved for example by the KW DDC coilovers.

Rebound damping

The rebound damping has a direct influence on the working speed when the piston rod rebounds. It also regulates how quickly the spring relaxes back to its original position. At different coilovers, the rebound stage can be adjusted. The diameters of the rebound valves are opened for a smoother ride and closed for tighter setup. The adjustable rebound damping affects the vehicle handling and comfort.

Compression damping

Different coilovers allow adjustments to the dampers independently of the rebound. With the compression level, the speed of the piston rod can be regulated during immersion. It has a direct influence on pitching and rolling movements of the body as well as on the steering behavior. If the valves are opened, the compression is reduced and the car dives in faster during steering movements. If the compression level is increased, the piston rod dives in slower. The more stable the vehicle acts during steering movements. If the compression damping is set stronger, the steering behavior is getting more precise. With some coilovers as for example the KW Clubsport 3-way suspensions, the compression level can even be set separately in low speed and high speed ranges.

The coilover suspension

In contrast to standard and sports suspension solutions, the coilovers have a thread and an adjustable spring plate. Via this thread, the spring plate can be rotated upwards or downwards to choose a continuous lowering. The upright position of the spring can be changed, which changes the height of the vehicle. The spring preload at standing height of the vehicle cannot be changed, this can only be influenced by the vehicle weight.

For example, while KW uses struts made of aluminum or stainless steel and a spring plate made of a composite material, other manufacturers merely coat the used steel struts and rely on aluminum spring plates for protection against corrosion.

One thing serious suspension manufacturers have in common: none of them uses the so-called bracket solution for lowering. Bracket solution is to shorten or lengthen the strut with a counter screw.

„At KW and ST, every suspension is adapted exactly to the conditions of the vehicle. There are only vehicle-specific applications, so that the maximum lowering is always achieved within the valid regulations and standards.”

„Already during development, we make sure that even with the maximum lowering there cannot be any damage at the axle joints, coupling rods, tie rods, drive shafts, brake lines, etc. In addition, we ensure the wheels clearance and that the parts located on the underbody, such as oil sump, axle or exhaust do not hit the road, even on extreme loads”, explains Thomas Wurst Head of KW R&D.

“With bracket solutions, this is up to the customer. Even slightly wrong settings will inevitably lead to damages of the vehicle. Besides, it is more than questionable whether countered housing screwing’s at wheel-guiding struts will bear in everyday life, as numerous forces act on the struts while driving. I would rather not think about problems caused by the corrosion of the counter-screws.”

Further information can be found on the websites of ST suspensions and KW.